|

Tech Notes: |

|

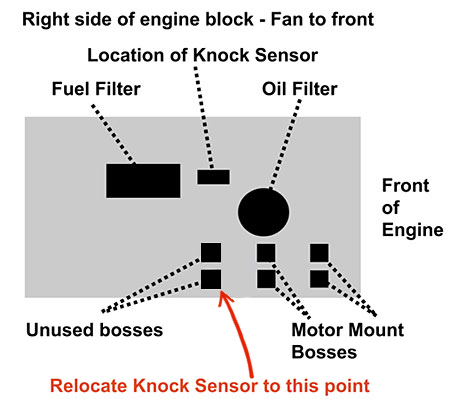

Knock Sensor Relocation

|

|

WARNING

WARNING WARNING WARNING

WARNING WARNING |

|

|

|

When FORGED PISTONS or any kind of

performance pistons have been installed in a fuel injected motor, you

MUST relocate the knock sensor.

Failure to relocate the sensor will result in

FATAL ENGINE DAMAGE.

The current location of the knock sensor is ideal for stock Toyota

engines. However, with the modifications to your particular engine,

which include forged performance pistons, this location causes problems.

PERFORMANCE PISTONS are noisier than other pistons and the knock

sensor picks up the noise as detonation or pinging. Upon sensing

this it retards engine conditions, such as cruising on the highway.

The retarded timing and excess fuel causes overheating on the exhaust side

of the upper piston ring land. Continued operation with this

condition will cause premature engine failure.

Removal of the knock sensor is not an option; this will cause the computer

to go into an open loop operation.

Relocate knock sensor by drilling and tapping on of the unused upper

bosses on the right side of the engine block. (See Illustration) Use

a .422 or 27/64" sized drill and a 12x1.25 tap.

PAY SPECIAL ATTENTION WHEN DRILLING THE BLOCK.

Don't drill any deeper than the current hole in the boss. By going to far,

you will drill through the block. Relocate the knock sensor to the

upper boss. Any questions? Call LC Engineering Technical

Department at 928-855-6341.

|

|

Knock Sensor Relocation: |

| |

| |

|

|

The 22RE Pro (forged piston) engines require relocation of the knock

sensor. Why? Here's the reason. The forged pistons create a

high-pitched knock when they are cold. The sensor hears this knock

and instructs the computer to take ignition timing away and add fuel

to the motor in order to combat detonation, which is not really

happening.

In order to prevent this, we relocate the knock sensor lower on the

block below the bore line. The sensor will still hear a detonation

on lean condition and react correctly, however, it is low enough on

the block to not hear forged piston's rocking. |

| |

|

Relocate the knock

sensor by drilling and tapping one of the un-used lower bosses on

the right side of the engine block. Use a .422 or 27/64" sized

drill bit and a 12mm x 1.25mm tap. PAY SPECIAL ATTENTION WHEN

DRILLING THE BLOCK. Do not drill any deeper than the current

hole in the boss. By going too far, you will drill through the block.

Now you can relocate the knock sensor to the lower boss. This is

shown in the attached photo.

If you use cast pistons in your rebuild, the knock sensor relocation

is not necessary. The cast pistons grow with heat faster than

forged pistons and do not rock in the bores.

Remember, removal of the knock sensor is not

an option: this will cause the computer to go into an open loop

operation. Not Good!

Any questions, give our tech line a call at 928-505-2501. |

|

|

|

|

|